*Purchase version of the Community Edition available starting March 10, 2026.

AlphadiTab

The first statistics tool built to be truly lean.

Feature Overview

• Bar Chart

• Pie Chart

• Boxplot

• Histogram

• Correlation Plot

• Time Series

• Pareto Chart

• Flowchart

• Normal

• Binomial

• Poisson

• Weibull

• Uniform

• Exponential

• Chi-Square

• Student’s t

• F

• Triangular

• Logistic

• Beta

• Gamma

• Lognormal

• Geometric

• Negative Binomial

• Johnson Distribution

• Normal

• Weibull

• Exponential

• Loglogistic

• Logistic

• Gamma

• Minimum Extreme Value

• Maximum Extreme Value

• Lognormal

• Anderson-Darling

• Shapiro-Wilk

• Kolmogorov-Smirnov

• Cramér-von-Mises

• I-MR Chart

• X-Bar Chart

• P Chart

• U Chart

• Worksheet Creation

• MSA Type 1

• MSA Type 2 (Continuous)

• MSA Type 2 (Attribute)

• Capability Analysis (Normal Data)

• Capability Analysis (Non-Normal Data)

• Proportion Test

• F-Test

• t-Test

• Levene’s Test for Equality of Variances

• ANOVA

• Power & Effect Size Analysis

• Sample Size Calculation

• Simple Linear Regression

• Two-Level Full Factorial Designs

• Design Creation and Analysis

• Linearity Checks

• Blocking

• Model Reduction

• Target Optimization

Full Functionality —

Without High Licensing Costs

More value for your team —

at a fair price.

Compared to other statistical software solutions, AlphadiTab offers a transparent, team-friendly pricing model. You get all the features you need for your projects — without unnecessary add-ons or hidden fees. Ideal for teams that want to combine efficiency with cost-effectiveness.

Community

Feb 6, 2026

Annual Plan

€250 per year (net)

- All features for unlimited use

- Data export

- Data management

Key Information at a Glance

Technical Specifications and Terms of Use

Specifications

Loading..........

The Data is Not Available

* RAM requirements may vary depending on dataset size.

Terms of Use

Quality / Accuracy of the Software

We place great importance on delivering high-quality products and services.

AlphadiTab is regularly reviewed and tested during our training programs by our testers and our internal team.

Target Audience

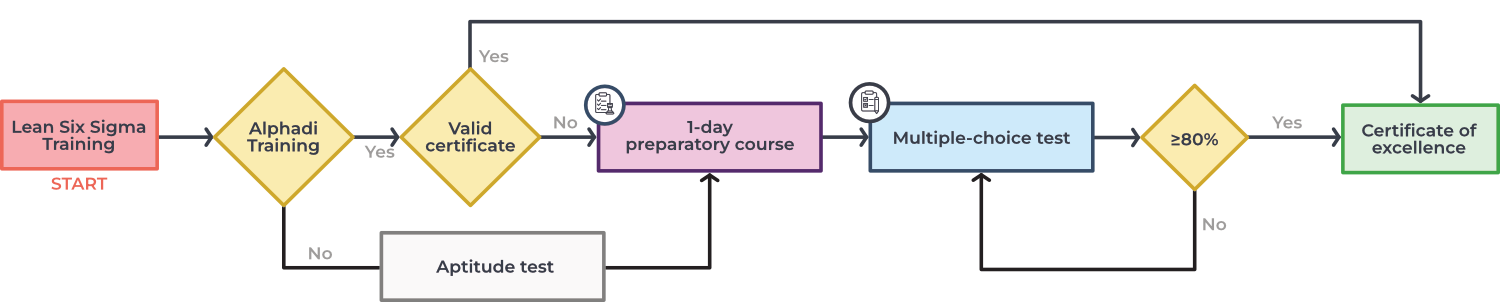

Our primary target group consists of Lean Six Sigma project leaders.

The software covers the core tools required for Green Belt certification.

Since Lean Six Sigma integrates methods from project management, statistics, Six Sigma, Lean, and quality management, AlphadiTab is also well suited for quality managers. The software supports users in conducting process capability analyses, measurement system analyses, and creating control charts.

Data Exchange with Servers

AlphadiTab is installed locally and does not access or retrieve any data from external servers without user consent.

The software does not collect or transmit user data.

No interfaces are available in the current version.

Hardware Interfaces: none

Software Interfaces: none

Communication Interfaces: none

Updates

Software updates are performed manually.

When improvements or bug fixes are implemented, the company will be informed. Communication is handled through Alphadi Deutschland GmbH.

All software updates are provided free of charge.

Upgrades

No upgrades are currently available.

However, upgrades are already in development and will be offered at an additional cost.

Multilingual Support

The software is available in German and English.

Data Protection

The software does not process any personal data.

Liability

Alphadi hereby disclaims all warranties, including but not limited to implied warranties of merchantability, fitness for a particular purpose, and non-infringement. All warranties that the information is free of errors, viruses, or defects of any kind are also expressly disclaimed.

In no event shall Alphadi be liable for any damages of any kind, including damages resulting from negligence in programming by Alphadi or its employees, arising out of or in connection with the use, transmission, or reliance upon the information provided.

Alphadi and/or its suppliers shall not be liable for any direct, indirect, incidental, consequential, or special damages whatsoever, including damages resulting from inability to use the software, loss of data, or loss of profits, whether based on breach of contract, negligence, or any other legal theory, arising out of or in connection with the use of documents, the provision or failure to provide services, or information available through the services.