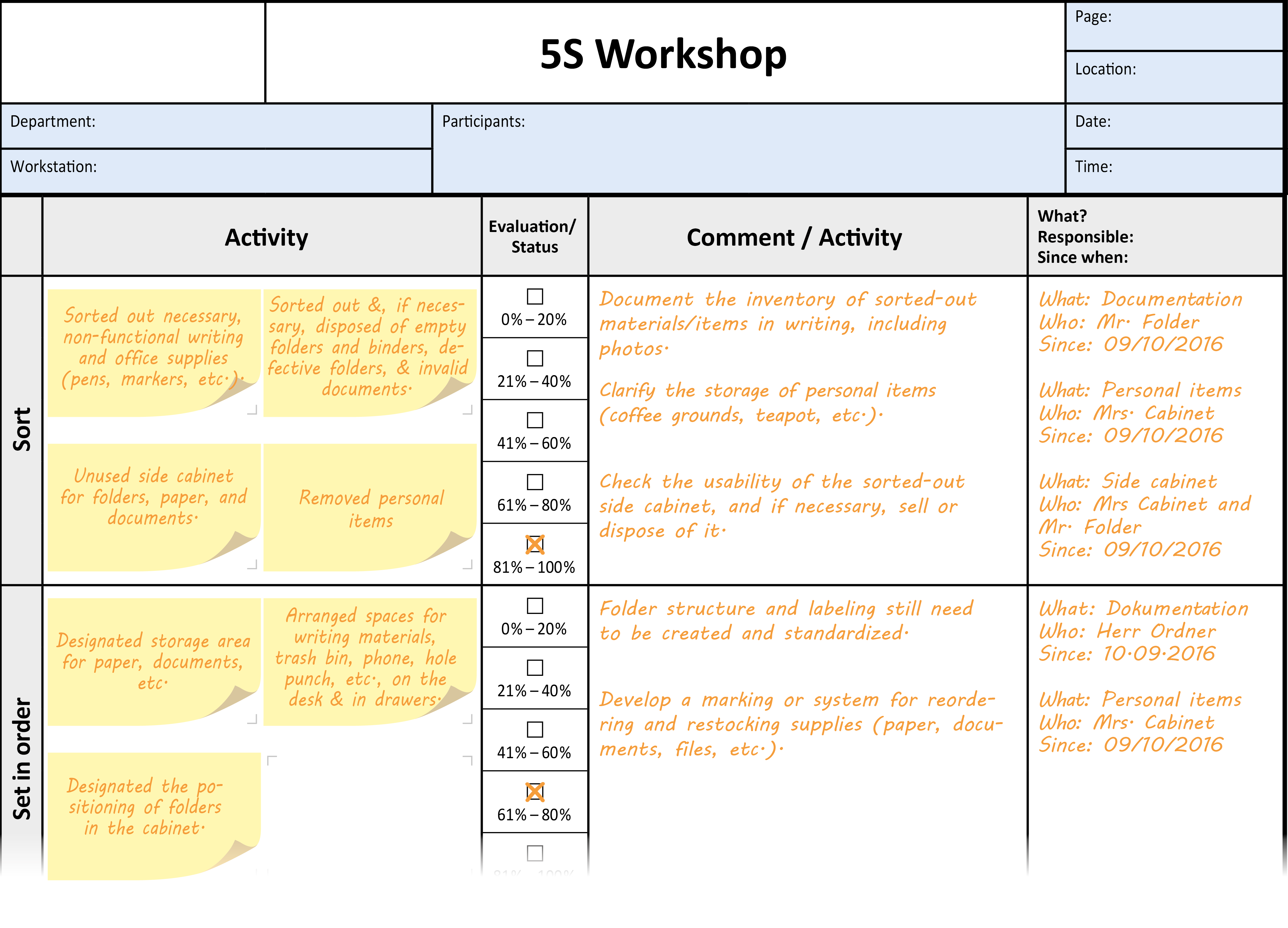

In the first step, remove items that are not needed for the workflow. The workstation becomes more organized and provides more space.

Start with the systematic arrangement of frequently used work materials/tools at the workstation. The arrangement can be based on frequency of use and/or order of use.

Employees thoroughly and regularly clean the workstation. During the cleaning process, the items are automatically checked for defects.

Create documentation to define the standards for the workstation. This may include color codes, fixed locations for materials, or a cleaning schedule, all of which can be standardized.

The new standards can be used as a checklist. Rules for organization and cleanliness become a habit. With 5S audits, the workstation organization can be evaluated for weaknesses.

With more than 4,000 projects and case studies, Alphadi is a leader in the field of Lean Six Sigma and Sales Process Engineering. We advise you holistically so that your goals are achieved sustainably and in the long term.

2024 © All Rights Reserved.